Storage

Energy Storage Resources

Storage technologies can be used to provide peaking generating capacity, load shifting, system support, operating reserves, and a variety of other ancillary services. Large pumped storage hydroelectric (PSH) facilities are the major energy storage technology applied for utility-scale applications. At present, about 99% of all utility-scale storage capacity in the world is in PSH. A typical PSH plant has a capacity of several hundred megawatts and is designed to provide about 8 to 10 hours of generation at full power output. These facilities are used primarily for daily load shifting but are also used for regulation control and spinning reserve applications. In addition to PSH, during the 1980s and 1990s, several lead-acid battery facilities were deployed; they had capacities up to 40 MW for applications requiring discharges of a few seconds up to a few hours. Furthermore, one compressed air energy storage (CAES) facility with a capacity of 110 MW for up to 10 hours is also available in the United States, and one with a capacity of 290 MW is operating in Germany.

The benefits from energy storage for utility applications include these: more reliable system operation and fewer financial losses due to poor-quality power and power outages; better integration of variable energy resources, such as wind and solar; load shifting or energy price arbitrage involving charging with low-priced “off-peak” energy for use later, when costs are high; and the availability of various ancillary services needed to operate the electric power grid.

Energy Storage Technologies

The two primary categories of storage technologies examined here are PSH and CAES.

PSH

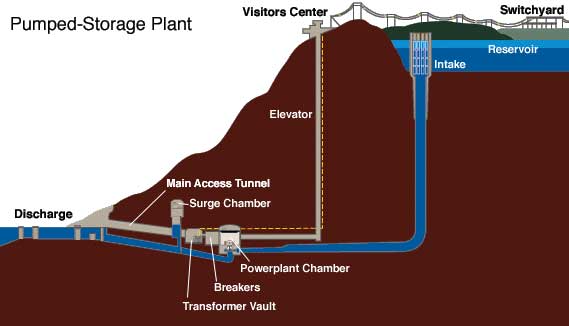

A PSH facility is typically equipped with pumps and generators that connect an upper reservoir and a lower reservoir (Figure 1). During off-peak hours, the pumps use cheap electricity from the power grid to move water from the lower reservoir to the upper reservoir in order to store energy. During periods of high electricity demand (peak hours), water is released from the upper reservoir to turn the turbines and to generate power as the water flows back into the lower reservoir.

There are two types of PSH facilities: off-stream (closed-loop) PSH and pump-back PSH. Off-stream or pure PSH facilities rely entirely on water that had previously been pumped into an upper reservoir as the source of energy, whereas pump-back or combined PSH facilities use both pumped water and natural stream flow water to generate power. The efficiencies of PSH facilities vary quite significantly due to the long history of the technology and the long lives of the facilities. At present, the total PSH cycle efficiency is typically between 70% and 85%.

CAES

CAES is used to store low-cost energy in the form of compressed air in an underground cavern or an aboveground vessel system during off-peak hours, and it is used to generate electricity during on peak hours. For CAES systems that use an underground cavern, the suitable geologies can be classified as salt (bedded and dome salt), aquifer, and rock. In general, to be suitable for underground air storage, a geological formation must be deep enough to allow safe operation at the required air pressure, porous enough to provide the required storage volume at the desired pressure, and permeable enough to permit the desired air flow rates. In addition, the mineralogy of the formation must not result in rapid chemical consumption of the oxygen in the stored air through oxidation reactions.

The energy conversion is achieved by releasing the compressed air from the storage reservoir; preheating the cool, high-pressure air; and directing the preheated air into an expansion turbine that drives an electric generator. The CAES systems operate in much the same way as a conventional gas turbine, except that the compression and expansion operations occur independently and at different times. Because compression energy is supplied separately, the full output of the combustion turbine can be used to generate electricity during operations; this is unlike a conventional gas-fired turbine, for which typically one-third of the output power is used to generate electricity and two-thirds is used to run the inlet compressor blades.

Reference

TVA (Tennessee Valley Authority), 2013, Hydroelectric Power, http://www.tva.gov/power/pumpstorart.htm.